Unlocking Automation: Limit Switch Wiring

Imagine a world without automatic doors, robotic arms, or even simple safety mechanisms in machinery. These conveniences and safeguards often rely on a small but powerful component: the limit switch. Understanding the circuitry behind these switches, often depicted in a limit switch wiring schematic, opens a window into the world of automation and control.

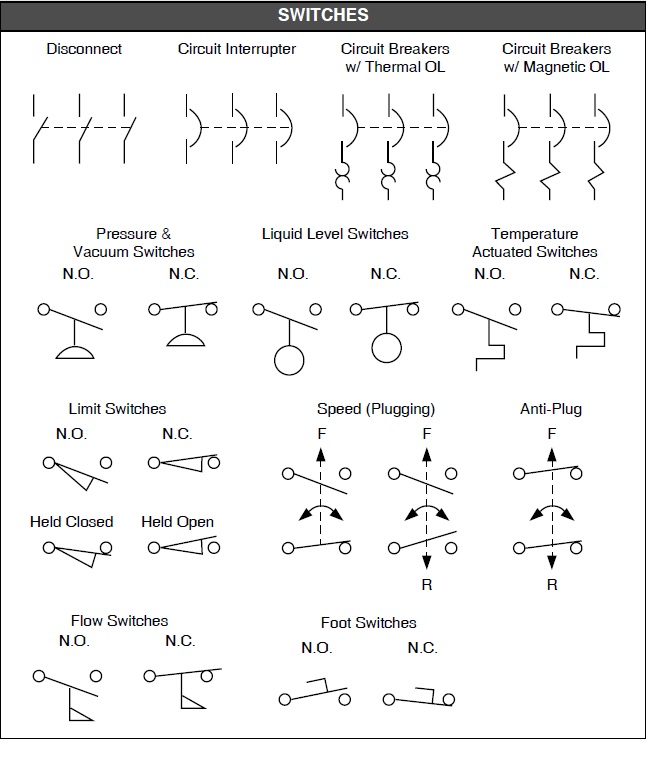

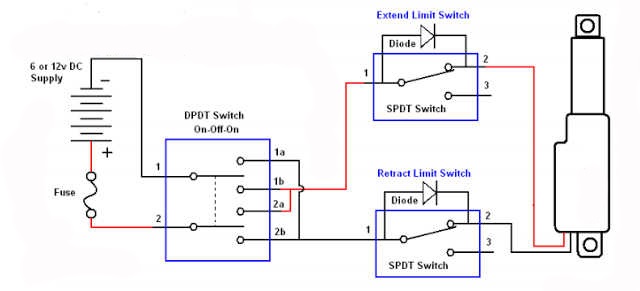

A limit switch wiring diagram, also known as a limit switch circuit diagram, is essentially a roadmap that illustrates how these switches are connected within a larger electrical system. It shows the path of electrical current, the components involved, and how the switch controls the flow of power. This graphical representation is crucial for anyone working with automated systems, from DIY enthusiasts building a garage door opener to engineers designing complex industrial machinery.

The concept of using a mechanical switch to control electrical circuits isn't particularly new. Early forms of limit switches emerged with the rise of industrialization and the need for automated machinery. As factories became more complex, the demand for reliable control systems grew, leading to the development of robust and versatile limit switches. Today, limit switch circuits are found everywhere, from household appliances to sophisticated manufacturing equipment.

The significance of a well-designed limit switch wiring schematic lies in its ability to ensure safe and efficient operation. An incorrect connection can lead to malfunctions, equipment damage, or even safety hazards. Understanding the intricacies of these diagrams is essential for troubleshooting issues, modifying existing systems, and designing new automated processes.

One of the key challenges related to limit switch wiring diagrams is ensuring compatibility between different components. Factors such as voltage, current ratings, and switch types must be carefully considered to avoid potential problems. For instance, using a switch with a lower current rating than the load it controls can lead to overheating and premature failure.

A simple example of a limit switch circuit is a garage door opener. The limit switch is positioned at the top and bottom of the door's travel path. When the door reaches either limit, the switch activates, cutting power to the motor and preventing the door from moving further, thus preventing damage.

Benefits of using limit switches include enhanced safety, improved efficiency, and increased automation. Safety is paramount, as limit switches prevent equipment from over-traveling, thus avoiding damage and potential injuries. Efficiency is improved through automation, as limit switches allow for precise control over machine operation. This precision leads to higher productivity and less waste. Finally, limit switches enable increased automation, freeing up human operators for more complex tasks.

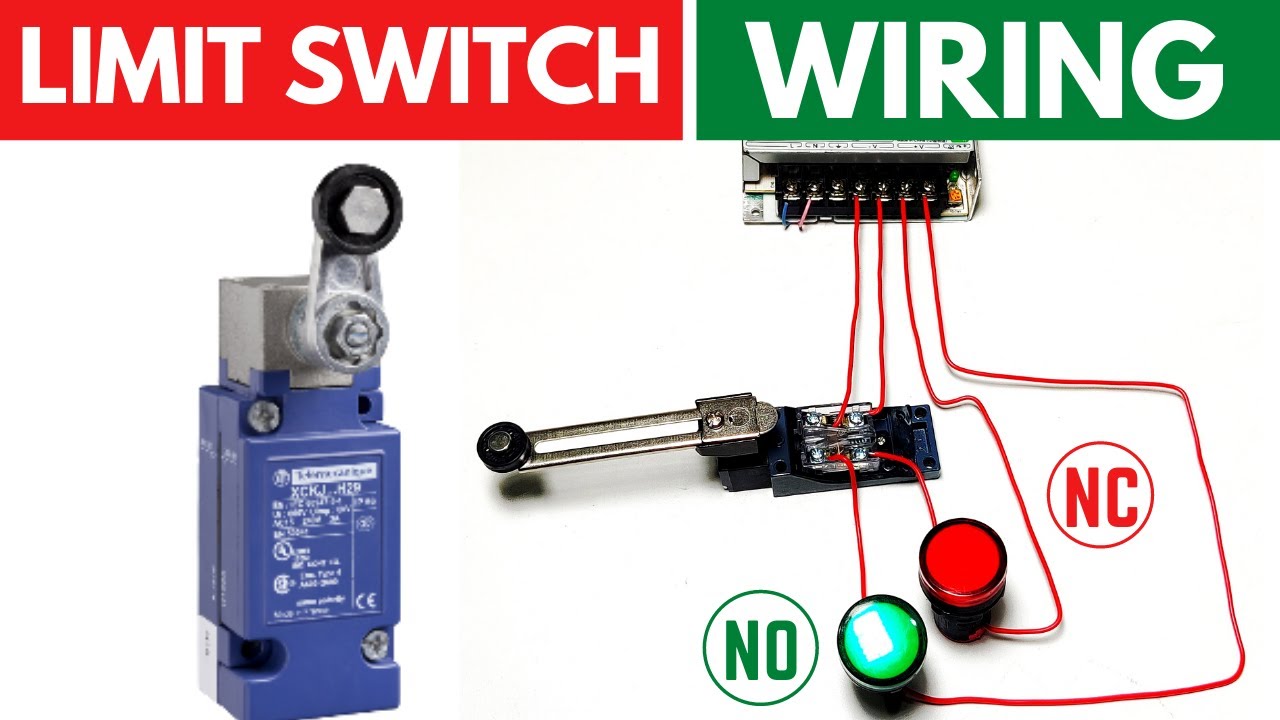

To implement a limit switch, one needs to identify the appropriate type of switch for the application, understand the voltage and current requirements, and connect the switch according to the wiring diagram. It's important to select a switch with the correct actuator type (lever, plunger, roller, etc.) for the intended mechanical action. Careful planning and execution are crucial for successful implementation.

Advantages and disadvantages of using limit switches:

Advantages and Disadvantages of Limit Switches

| Advantages | Disadvantages |

|---|---|

| Simple and reliable | Can be prone to mechanical wear |

| Cost-effective | Limited lifespan compared to other sensor technologies |

| Versatile for various applications | Susceptible to environmental factors (dust, moisture) |

Best practices for implementing limit switches include choosing the right switch for the application, ensuring proper wiring, and regular maintenance. It's also important to consider the environment in which the switch will operate, selecting a switch with appropriate protection ratings for dust, moisture, and temperature.

Real-world examples of limit switches include controlling the travel of cranes, stopping conveyor belts at designated points, and preventing overfilling in tanks.

Challenges associated with limit switches include mechanical wear, susceptibility to environmental factors, and potential for miswiring. Solutions include regular maintenance, selecting appropriate environmental protection ratings, and careful adherence to wiring diagrams.

Frequently asked questions include: How do I choose the right limit switch? How do I wire a limit switch? What are the common problems with limit switches? What are the different types of limit switches?

Tips and tricks include checking the wiring diagram carefully, ensuring proper grounding, and testing the circuit thoroughly before operation. Regularly inspect the switches for signs of wear or damage.

In conclusion, understanding limit switch electrical diagrams is crucial for anyone working with automated systems. These diagrams provide a roadmap for safe and efficient operation, enabling precise control, enhancing safety, and increasing automation. While challenges like mechanical wear and environmental factors exist, proper implementation, regular maintenance, and adherence to best practices ensure reliable and long-lasting performance. By learning the intricacies of limit switch circuits, you unlock the power of efficient and safe automation, contributing to a more productive and secure operational environment. This knowledge empowers you to troubleshoot issues effectively, design new control systems, and leverage the full potential of limit switches in your projects, from simple DIY endeavors to complex industrial applications. Embracing this knowledge allows you to build smarter, safer, and more efficient systems, contributing to a future where automation enhances our lives in countless ways.

Unveiling the mystery black knight fortnite skins worth

Fifa 23 nintendo switch edition deep dive

Conquer the oakville g test route your ultimate guide