Understanding Ignition Coil Circuitry

Ever wondered about the magic that sparks your engine to life? It's not magic, but the precise choreography of the ignition coil circuit. This network of electrical components, including the ignition coil wiring diagram, plays a crucial role in transforming low voltage from the battery into the high voltage needed to ignite the air-fuel mixture in your engine's cylinders. Understanding this system is key to maintaining a smooth-running and efficient engine.

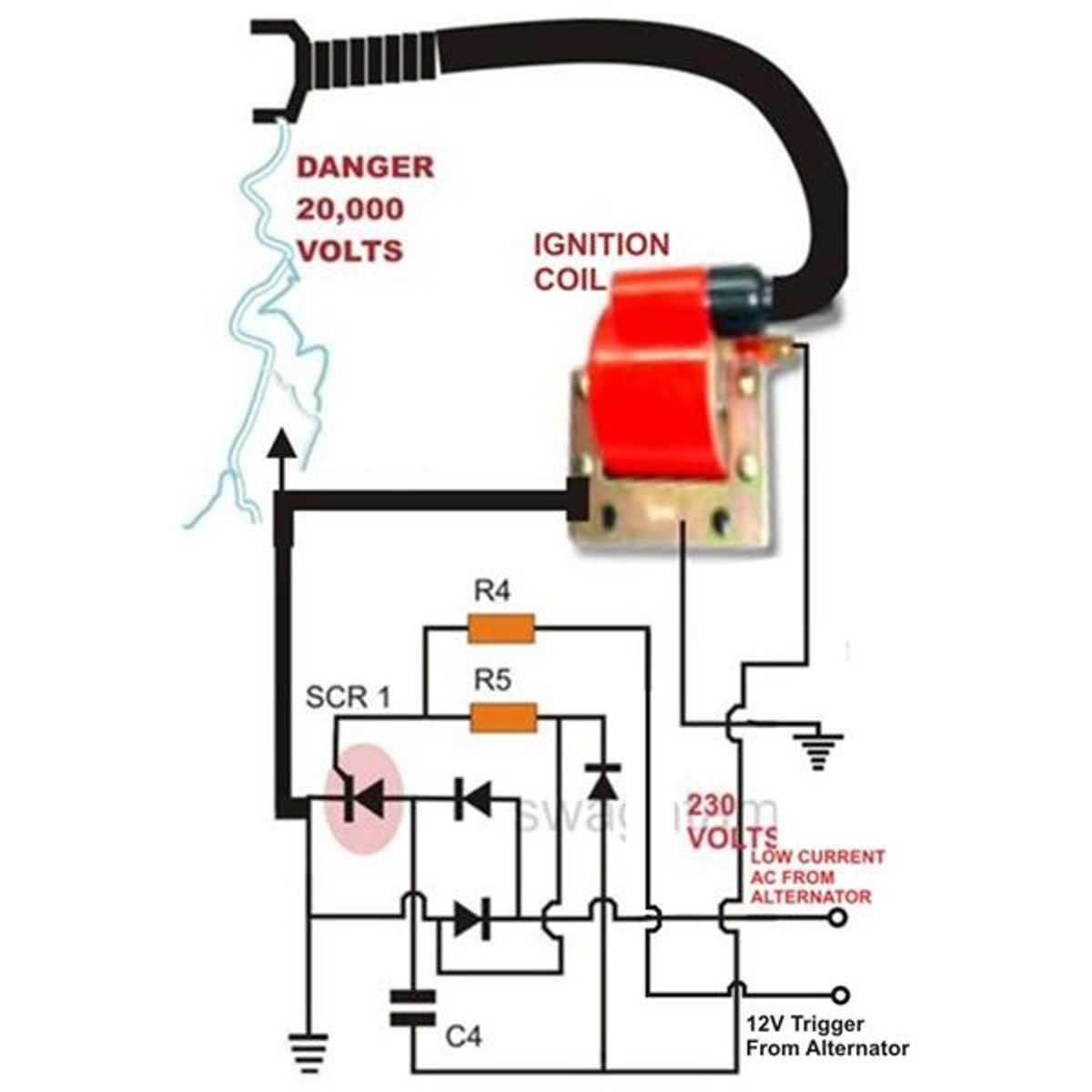

The ignition coil circuit, often visualized through an ignition coil diagram, is essentially a high-voltage transformer. It takes the relatively low voltage of the vehicle's battery (typically 12 volts) and steps it up to thousands of volts, enough to jump the gap of the spark plugs and initiate combustion. This high voltage pulse, delivered at the precise moment, is the heart of internal combustion engine operation. A faulty ignition coil schematic can lead to misfires, poor fuel economy, and even engine damage.

The history of the ignition coil circuit is intertwined with the development of the internal combustion engine itself. Early ignition systems were quite rudimentary, evolving from simple magneto systems to the more complex electronic ignition systems we see today. Understanding the evolution of the ignition coil circuit provides valuable insight into how engine technology has progressed over time. Modern electronic ignition systems, guided by a precise ignition coil wiring schematic, offer improved efficiency, performance, and reliability compared to their predecessors.

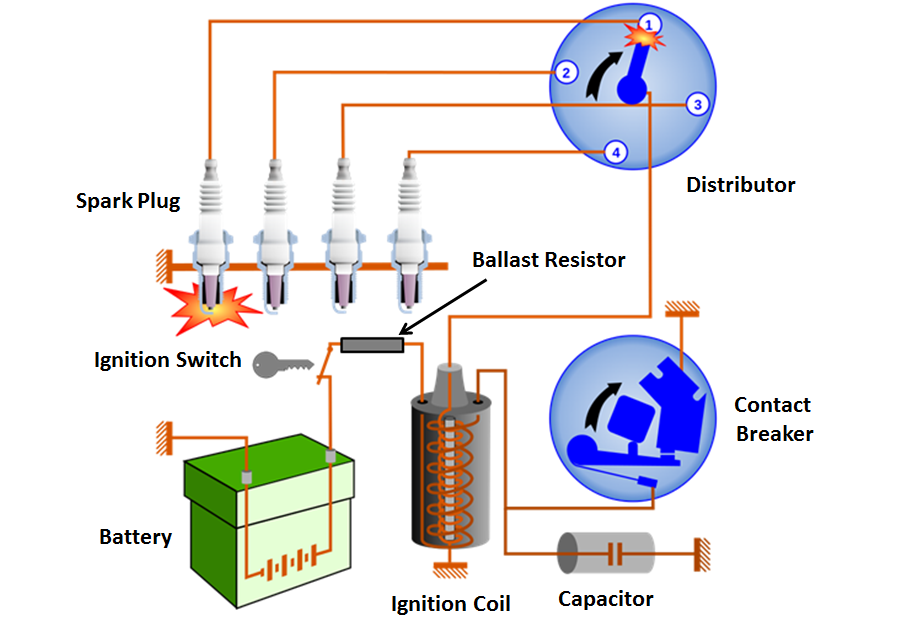

The ignition coil circuit diagram is essentially a roadmap of the electrical flow within the ignition system. It illustrates the connections between the battery, ignition switch, ignition coil, distributor (in older systems), and spark plugs. A comprehensive understanding of the ignition coil schematic is essential for diagnosing and troubleshooting ignition system problems. It allows mechanics and enthusiasts alike to trace the flow of electricity and pinpoint the source of malfunctions. This diagram is an invaluable tool for anyone working on an engine.

Different types of ignition coil setups exist, from single coil systems to coil-on-plug (COP) systems, each with its own unique ignition coil circuit design. In single coil systems, one coil serves all the spark plugs, distributing the high voltage through a distributor. COP systems, on the other hand, have a dedicated coil for each spark plug, eliminating the need for a distributor and often leading to improved performance and reliability. Each system’s schematic offers specific insights into its operation.

The importance of a properly functioning ignition coil circuit cannot be overstated. It directly impacts the engine's ability to start, run smoothly, and deliver optimal power and fuel efficiency. A failing ignition coil can cause a range of problems, from rough idling and misfires to complete engine failure. Understanding the intricacies of your vehicle's ignition coil system, as detailed in its specific diagram, is crucial for maintaining peak performance and avoiding costly repairs.

One example of an ignition coil circuit is the system found in a typical four-cylinder engine with a distributor. The circuit begins with the battery, then to the ignition switch. Power flows to the ignition coil, which generates high voltage. This voltage is then distributed to the spark plugs in the correct firing order by the distributor.

Three key benefits of a well-maintained ignition coil circuit are: 1) Improved Fuel Economy: A strong spark ensures complete combustion, leading to better fuel efficiency. 2) Increased Engine Power: Optimized ignition timing maximizes power output. 3) Reduced Emissions: Complete combustion minimizes unburnt fuel, resulting in fewer harmful emissions.

Advantages and Disadvantages of Different Ignition Coil Systems

| System | Advantages | Disadvantages |

|---|---|---|

| Single Coil | Simple, Cost-Effective | Less efficient, potential for wear on distributor components |

| Coil-on-Plug (COP) | Improved performance, greater reliability | More expensive than single coil systems |

Best Practices for Maintaining Ignition Coil Circuits:

1. Regularly check spark plugs and replace as needed.

2. Inspect ignition wires for damage and replace if necessary.

3. Ensure proper connections and wiring according to the ignition coil diagram.

4. Test the ignition coil using a multimeter to check for proper resistance.

5. Keep the engine compartment clean and free of debris to prevent corrosion and electrical shorts.

Frequently Asked Questions:

1. What does an ignition coil do? It transforms low voltage to high voltage to ignite the fuel-air mixture.

2. What are the symptoms of a bad ignition coil? Misfires, rough idling, difficulty starting, reduced fuel economy.

3. How can I test an ignition coil? Use a multimeter to check for proper resistance.

4. How often should I replace my ignition coil? Consult your vehicle's maintenance schedule.

5. What is a coil-on-plug system? A system with a dedicated ignition coil for each spark plug.

6. Can a bad ignition coil damage my engine? Yes, prolonged misfires can lead to engine damage.

7. What is the purpose of an ignition coil circuit diagram? It shows the electrical connections within the ignition system.

8. Where can I find an ignition coil circuit diagram for my car? Consult your vehicle's repair manual.

In conclusion, the ignition coil circuit, often detailed in an ignition coil wiring diagram or ignition coil schematic, is a fundamental component of any internal combustion engine. Its efficient operation is vital for smooth running, optimal performance, and good fuel economy. Understanding the basics of how this system works, recognizing potential problems, and implementing best practices for maintenance will ensure your engine runs smoothly for years to come. Taking the time to familiarize yourself with your vehicle's specific ignition coil circuit diagram empowers you to address issues proactively and maintain peak performance. Regular maintenance, coupled with a thorough understanding of the system, will keep your engine running smoothly and efficiently, minimizing the risk of costly repairs down the road. Don't underestimate the power of a well-maintained ignition system – it's the spark that keeps your engine alive!

The filthy rich hamster who owns the apocalypse

Transform your voice the ultimate guide to voice changing

Unlocking futures exploring educational zakat aid in kedah