The Silent Guardian of Water Flow Pressure Switch Connections

Consider the seemingly simple act of turning on a faucet. Water flows, effortlessly and on demand. But behind this everyday miracle lies a network of carefully orchestrated mechanisms, and at the heart of it all, often unseen and unsung, resides the pressure switch. This small but mighty component, the pressure switch for your water pump, acts as the conductor of this watery orchestra, ensuring a seamless symphony of pressure and flow.

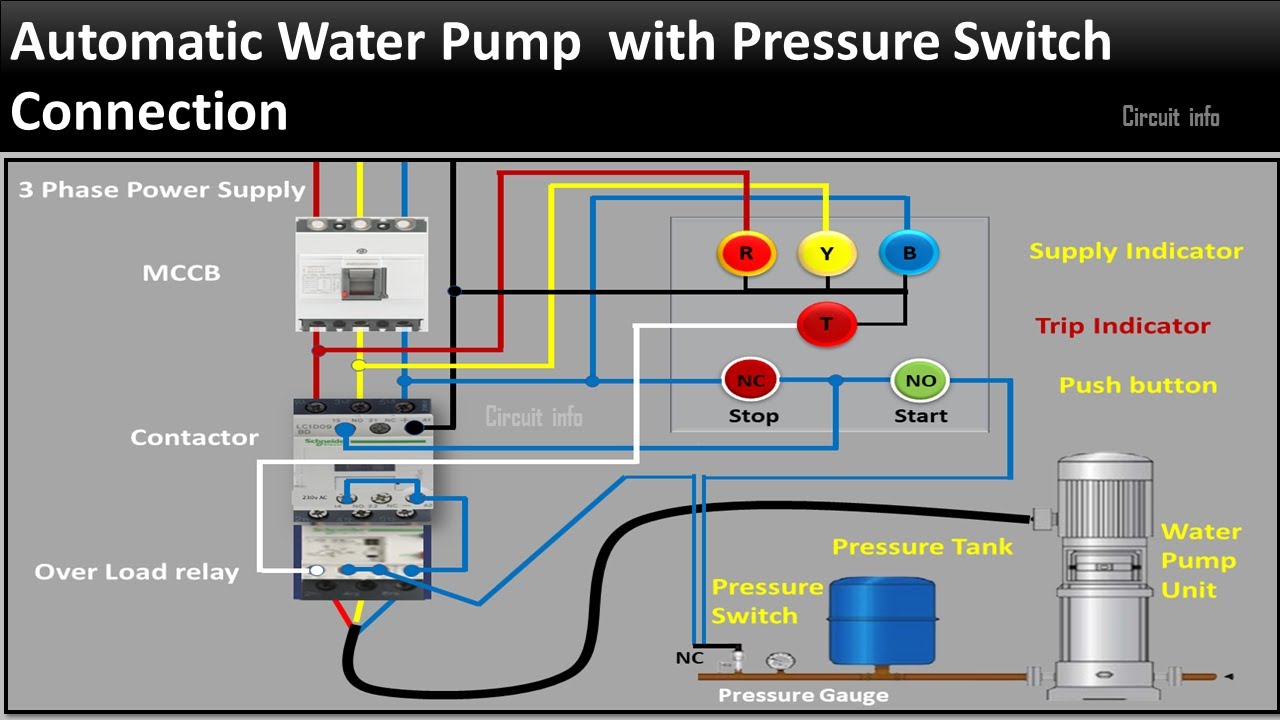

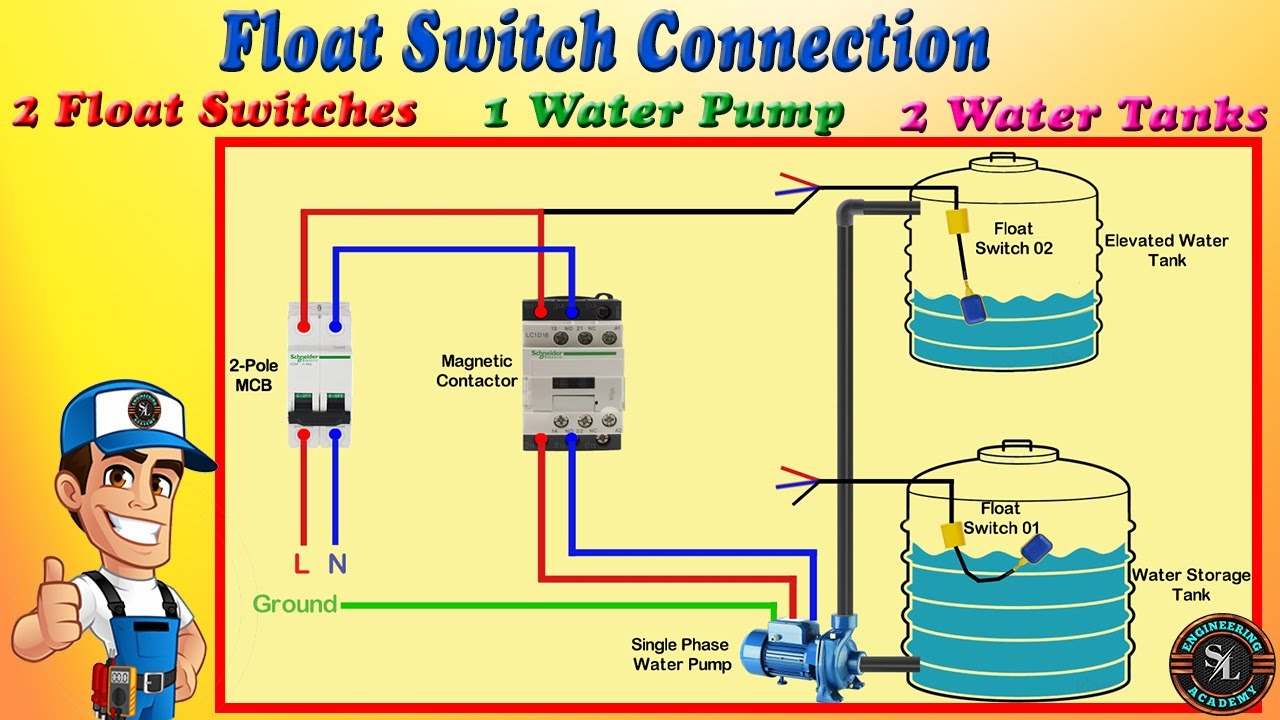

The pressure switch, in its quiet diligence, monitors the water pressure within the plumbing system. When the pressure drops below a preset threshold, perhaps because a faucet is opened or a toilet is flushed, the switch activates the pump, bringing the pressure back up. Conversely, when the demand ceases and the pressure rises again, the switch deactivates the pump, preventing over-pressurization. This constant dance of activation and deactivation ensures a consistent water supply, shielding us from the inconveniences of fluctuating pressure and potential damage to the plumbing system.

The history of pressure control mechanisms is interwoven with the development of pumping technologies themselves. From the earliest hand pumps to the sophisticated systems we rely on today, the need to regulate pressure has been a constant. Early pressure control methods were often mechanical, relying on springs and valves. The advent of electrical switches marked a significant advancement, allowing for more precise and automated control. The evolution of pressure switch technology reflects our ongoing quest for more efficient and reliable water management solutions.

Understanding the pressure switch connection for your water pump is crucial for maintaining a properly functioning water system. A faulty connection can lead to a myriad of problems, including erratic water pressure, pump short-cycling (frequent starting and stopping), and even complete pump failure. This underscores the importance of proper installation and regular maintenance of the pressure switch and its associated connections. It's the silent guardian, ensuring the smooth operation of our water systems.

The pressure switch operates on a simple but elegant principle. Inside the switch, a diaphragm senses changes in water pressure. When the pressure drops below the "cut-in" setting, the diaphragm moves, closing an electrical circuit and activating the pump. As the pressure rises and reaches the "cut-out" setting, the diaphragm moves back, opening the circuit and deactivating the pump. This precise control loop maintains the desired pressure range within the system.

Benefits of a Properly Functioning Pressure Switch Connection:

1. Consistent Water Pressure: A correctly wired and adjusted pressure switch guarantees a steady and reliable water supply, eliminating frustrating fluctuations in pressure.

2. Protection of the Pump and Plumbing System: By preventing over-pressurization and short-cycling, the pressure switch protects the pump motor from excessive wear and tear, extending its lifespan. It also safeguards the plumbing system from potential damage caused by high pressure.

3. Energy Efficiency: By ensuring the pump only runs when needed, the pressure switch optimizes energy consumption, reducing electricity bills.

Advantages and Disadvantages of Pressure Switches

| Advantages | Disadvantages |

|---|---|

| Automated Pressure Control | Potential for Malfunction |

| Protection of Pump and Plumbing | Requires Periodic Adjustment |

| Energy Efficiency | Sensitivity to Water Quality |

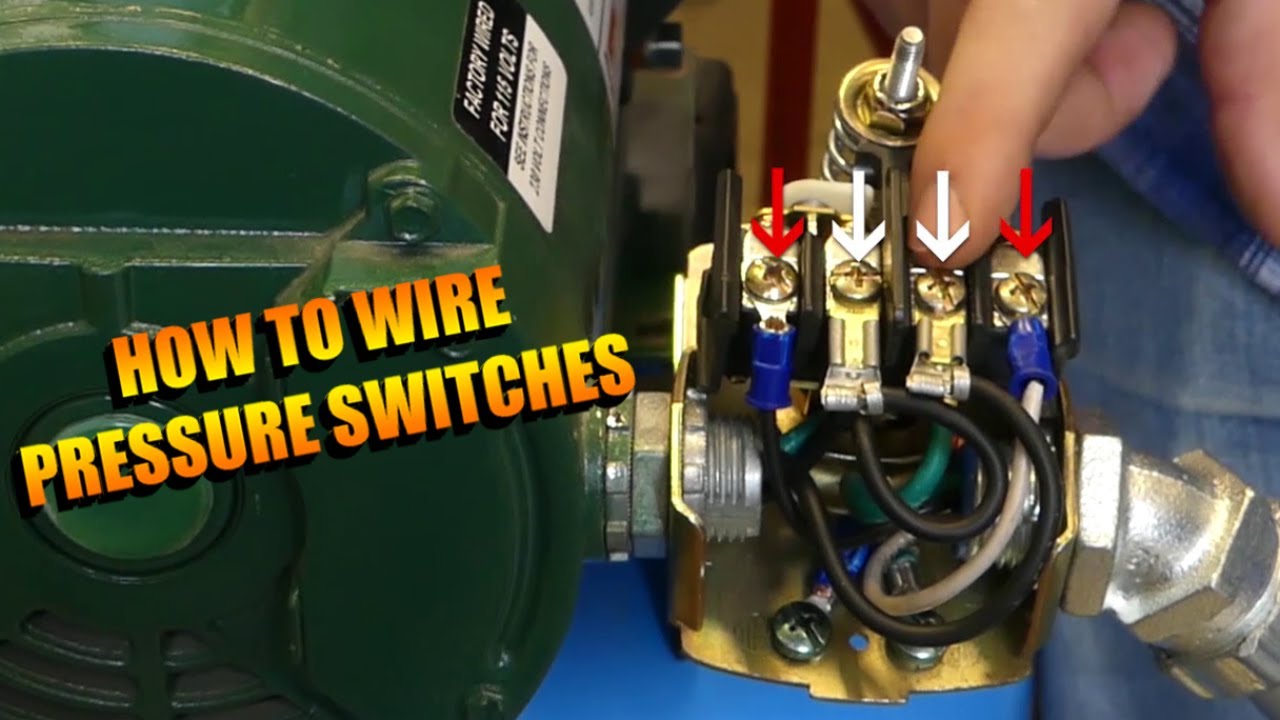

Best Practices for Pressure Switch Connection:

1. Consult the manufacturer's instructions: Always follow the specific guidelines provided by the manufacturer for your particular pressure switch model.

2. Use appropriate wiring and connectors: Ensure all wiring and connectors are properly sized and rated for the electrical load of the pump.

3. Securely tighten all connections: Loose connections can lead to electrical problems and pressure fluctuations.

4. Use Teflon tape on threaded connections: This prevents leaks and ensures a tight seal.

5. Test the system thoroughly after installation: Verify that the pressure switch is functioning correctly and maintaining the desired pressure range.

Frequently Asked Questions:

1. What is a pressure switch? (A device that controls a pump based on water pressure.)

2. How does a pressure switch work? (It uses a diaphragm to sense pressure changes and activate/deactivate the pump.)

3. How do I adjust the pressure settings? (Consult the manufacturer's instructions.)

4. Why is my pump short-cycling? (Possible pressure switch malfunction, leaks, or other issues.)

5. How do I know if my pressure switch is bad? (Inconsistent pressure, pump constantly running or not running at all.)

6. What are the common pressure switch problems? (Diaphragm failure, contact issues, clogged pressure port)

7. Can I replace a pressure switch myself? (Yes, with basic plumbing skills and by following instructions.)

8. Where can I buy a pressure switch? (Hardware stores, plumbing supply stores, online retailers.)

Tips and Tricks: Regularly inspect the pressure switch for signs of wear or damage. Check the pressure gauge reading to ensure it's within the desired range. If you experience any problems with your water pressure, consult a qualified plumber.

In conclusion, the pressure switch connection for your water pump is a vital component of a well-functioning water system. It ensures consistent water pressure, protects the pump and plumbing, and promotes energy efficiency. By understanding its function, proper installation procedures, and troubleshooting techniques, you can ensure a reliable and uninterrupted water supply for years to come. Regular maintenance and attention to detail will prevent potential problems and extend the life of your pump and pressure switch. Don't underestimate the significance of this small but mighty device – it's the silent guardian of your water flow, ensuring that every turn of the faucet brings forth the life-sustaining resource we often take for granted. Taking care of your pressure switch is an investment in the comfort and convenience of your daily life.

Powering up understanding 110 to 220 motor wiring

The essential role of the marine water pump impeller

Nepal public holidays today unveiled