Stranded Wire vs Solid Wire: Unraveling the Differences

Choosing the right wire for your electrical project can feel like navigating a labyrinth of options. One of the most fundamental decisions you'll face is selecting between stranded and solid core wire. This seemingly simple choice can significantly impact your project's success, so understanding the nuances of each is crucial. Let's embark on a journey to unravel the mysteries and discover the perfect wire for your needs.

At first glance, a wire is simply a conductor of electricity. However, delve deeper, and you'll uncover a world of subtle distinctions that determine a wire's suitability for various applications. Stranded wire, composed of multiple thin wires twisted together, offers flexibility and durability in dynamic environments. Solid wire, a single, thick conductor, provides strength and stability for fixed installations. This essential difference lays the foundation for understanding the distinct advantages and disadvantages of each type.

The history of wire development is intertwined with the evolution of electricity itself. Early experiments relied on single, solid conductors. As technology advanced, the demand for more flexible and resilient wiring solutions led to the development of stranded wire. This innovation opened up new possibilities for applications in moving machinery, electronics, and other dynamic systems. Understanding the historical context helps appreciate the significance of these seemingly simple yet powerful conductors.

Choosing between stranded and solid wire isn't merely a technical detail; it's a critical decision that can influence the safety, reliability, and longevity of your electrical systems. Using the wrong type of wire can lead to premature failures, connection issues, and even safety hazards. Therefore, a thorough understanding of the characteristics of each wire type is paramount for making informed choices.

Solid wire consists of a single, thick conductor, typically copper or aluminum. This robust structure offers excellent conductivity and rigidity, making it ideal for applications where the wire remains stationary. Stranded wire, on the other hand, comprises multiple thin wires twisted together, providing flexibility and resilience against bending and flexing. This construction makes it well-suited for applications involving movement or vibration.

One key benefit of stranded wire is its flexibility. This allows it to easily navigate tight spaces and withstand repeated bending without breaking. Imagine wiring a robotic arm; the constant motion requires a wire that can bend without compromising its integrity. Stranded wire is the perfect solution in this scenario.

Another advantage of stranded wire lies in its durability under vibration. The individual strands within the wire can move slightly against each other, absorbing vibrations and preventing fatigue. This makes it ideal for applications in vehicles, appliances, and other environments subject to vibrations. Conversely, solid core wire is susceptible to cracking under repeated vibration.

Stranded wire also exhibits superior resistance to metal fatigue, which is the weakening of metal due to repeated stress. The individual strands within the wire can flex and move independently, distributing stress and preventing premature failure. This makes stranded wire suitable for applications where the wire is subject to continuous flexing or bending.

Advantages and Disadvantages of Stranded vs. Solid Wire

| Feature | Stranded Wire | Solid Wire |

|---|---|---|

| Flexibility | High | Low |

| Durability under vibration | High | Low |

| Resistance to metal fatigue | High | Low |

| Ease of termination | Can be challenging | Easy |

| Cost | Generally higher | Generally lower |

Best Practices:

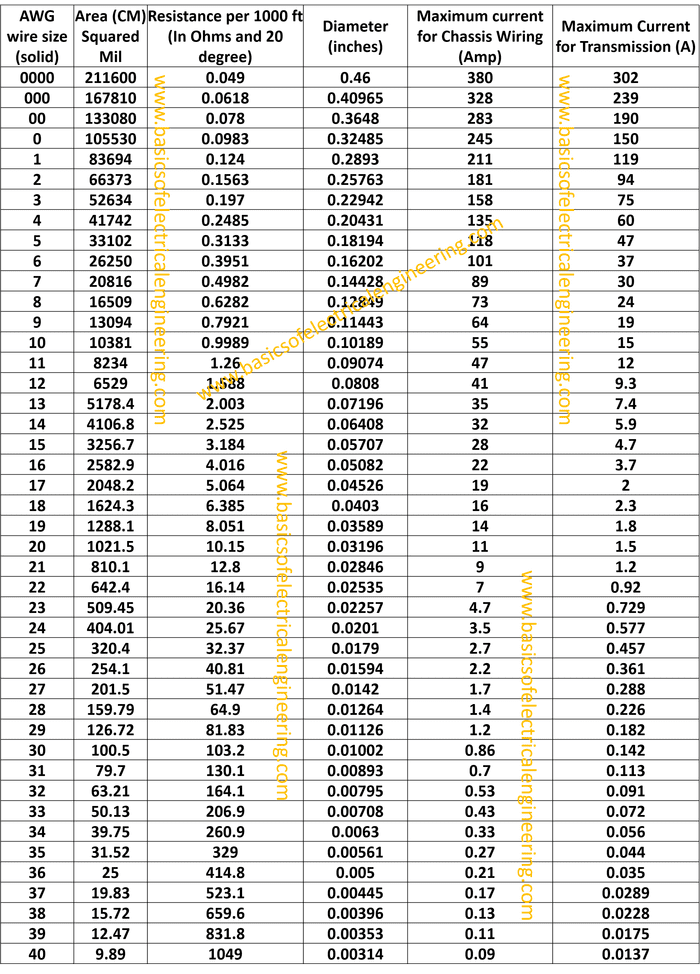

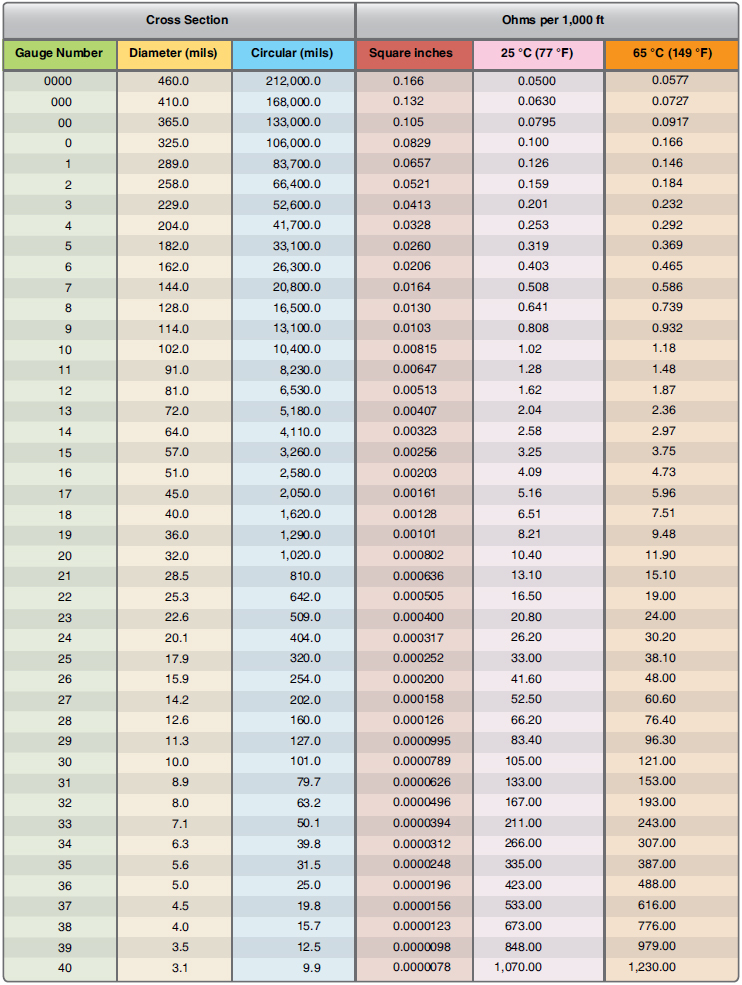

1. Choose the right gauge: Select the appropriate wire gauge based on the current requirements of your circuit.

2. Proper termination: Use appropriate connectors and techniques to ensure secure and reliable connections.

3. Strain relief: Provide adequate strain relief to prevent stress on the wire terminations.

4. Protection: Use appropriate conduit or cable management systems to protect wires from damage.

5. Environmental considerations: Choose wire with insulation rated for the intended environment (e.g., temperature, moisture).

FAQ:

1. What is the main difference between stranded and solid wire? Stranded wire is flexible, while solid wire is rigid.

2. Which wire is better for high-vibration environments? Stranded wire.

3. Which wire is easier to terminate? Solid wire.

4. Which wire is typically more expensive? Stranded wire.

5. What is wire gauge? Wire gauge refers to the thickness of the wire.

6. Why is proper termination important? To ensure a reliable and safe electrical connection.

7. What is strain relief? Strain relief prevents stress on the wire and its connections.

8. Why is choosing the right wire insulation important? To protect the wire from environmental factors and prevent shorts.

Tips and Tricks: When working with stranded wire, use ferrules or twist the strands together before inserting them into terminal blocks to prevent fraying and ensure a secure connection. For solid core wire, make sure the wire is straight and fully inserted into the terminal block.

In conclusion, the choice between stranded and solid wire depends entirely on the specific application. Stranded wire excels in dynamic environments requiring flexibility and vibration resistance, while solid wire is ideal for stationary applications where rigidity and cost-effectiveness are paramount. Understanding the unique characteristics of each type allows you to make informed decisions, ensuring the safety, reliability, and longevity of your electrical systems. By carefully considering factors like flexibility, durability, and ease of termination, you can select the perfect wire for your project, creating a solid foundation for electrical success. This knowledge empowers you to confidently navigate the world of wiring, ensuring that your electrical projects are not only functional but also safe and durable. Take the time to assess your project's needs and choose wisely – your electrical system will thank you.

Minecraft mastering the art of inversion

Decoding the hair over one eye look

Navigating the unam law curriculum