Imperial vs Metric Bolts Decoded Save Time and Money

Ever find yourself staring at a jumble of bolts, wondering which one is right? You're not alone! The difference between imperial and metric bolts can be confusing, but understanding it is crucial for any DIYer, mechanic, or engineer. Picking the wrong bolt can lead to anything from a stripped thread to a catastrophic failure. So, let's dive into the nuts and bolts (pun intended!) of this essential fastener knowledge.

The imperial system, with its inches and fractions, is a holdover from the British Empire. Metric, on the other hand, is the global standard, built on the cleaner, decimal-based system. This fundamental difference permeates every aspect of bolt selection, from sizing to wrench compatibility. Imagine trying to force a metric wrench onto an imperial bolt – it’s a recipe for frustration and potentially damaged equipment.

The origins of these systems date back centuries. Imperial measurements evolved organically over time, while the metric system was a product of the French Revolution, designed for simplicity and consistency. This historical context explains why imperial measurements seem so arbitrary (1/16th of an inch, really?) compared to the logical progression of metric units. The importance of understanding these differences becomes clear when you consider the global nature of manufacturing. A project designed with imperial fasteners might face compatibility issues if components are sourced from countries using the metric system.

One of the main challenges arising from the coexistence of these two systems is the potential for mismatches. A slightly-off size can lead to stripped threads, loose connections, and even structural failure. This is especially critical in applications where safety is paramount, such as automotive repair or construction. Think about the consequences of a wheel coming loose because the wrong bolt was used – a scary thought!

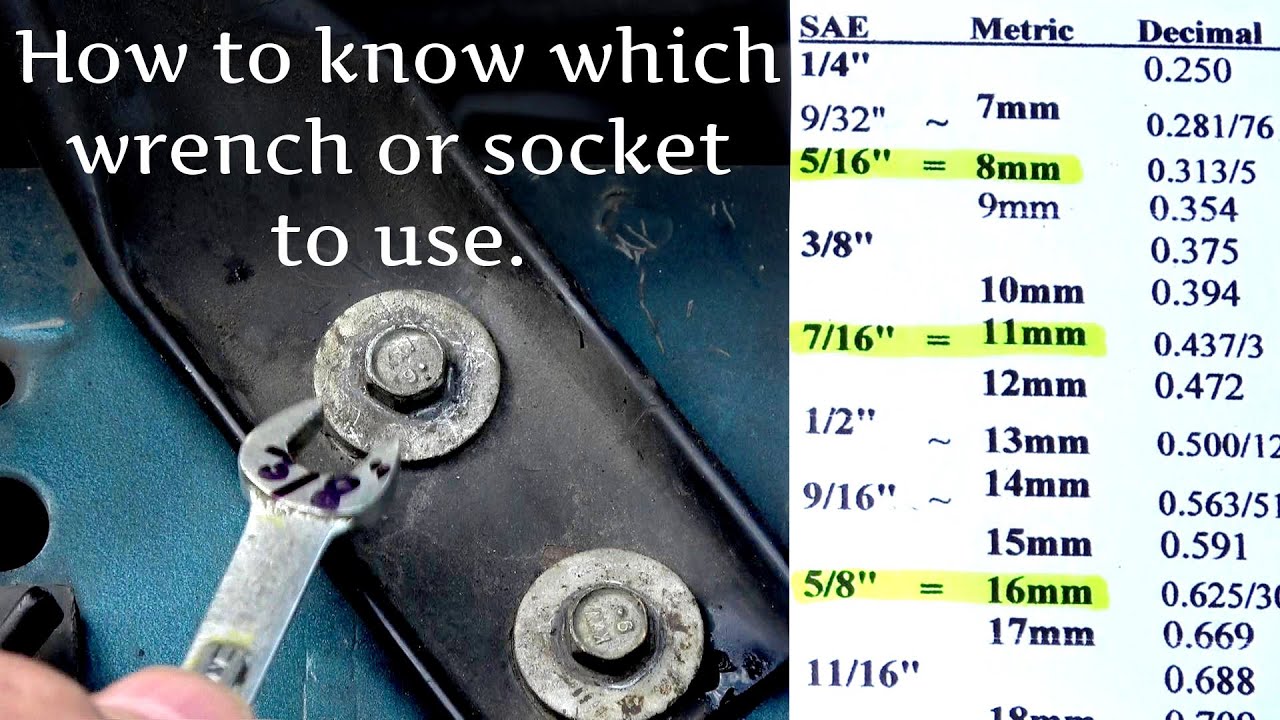

So, how can you tell the difference? Imperial bolts are often identified by fractions of an inch, while metric bolts are measured in millimeters. Look closely at the bolt head – you might see markings indicating the thread pitch or diameter. A quick visual inspection can save you a lot of headaches down the line. For instance, a 1/4-inch bolt will have a noticeably different diameter than a 6mm bolt, even though they might appear similar at first glance. Additionally, metric bolts frequently have numerical markings on their heads, whereas imperial bolts often do not.

Identifying imperial and metric bolts is crucial for avoiding project mishaps. Check thread pitch, head markings, and overall dimensions. When in doubt, consult a thread gauge or a knowledgeable hardware store employee. Remember, precision is key! A well-chosen bolt ensures a secure and lasting connection, preventing potential disasters and saving you time and money on repairs.

Unfortunately, there aren't direct "benefits" of the *difference* itself. The real benefit is understanding the difference and applying that knowledge. Using the correct system for your specific project ensures compatibility, safety, and efficiency.

Advantages and Disadvantages of Each System

| Feature | Imperial | Metric |

|---|---|---|

| Prevalence | Common in older US applications | Global standard |

| Ease of Use | Fractions can be less intuitive | Decimal system is simpler |

| Availability | Readily available in the US | Widely available worldwide |

FAQs

Q: What's the most common mistake people make with bolts?

A: Mixing imperial and metric fasteners.

Q: How can I tell if a bolt is imperial or metric?

A: Check for markings on the head or measure the thread pitch.

Q: What's the difference between coarse and fine threads?

A: Coarse threads are for general use, while fine threads are for more precise applications.

Q: Can I use an imperial wrench on a metric bolt?

A: Not recommended, as it can damage both the bolt and the wrench.

Q: Where can I find more information about bolt sizes?

A: Engineering handbooks and online resources.

Q: What are the consequences of using the wrong bolt?

A: Stripped threads, loose connections, and potential failure.

Q: How can I ensure I'm using the correct bolt?

A: Carefully measure and identify the required specifications.

Q: What tools do I need for working with bolts?

A: Wrenches, sockets, and possibly thread gauges.

Understanding the difference between imperial and metric bolts isn’t just about avoiding frustration—it’s about ensuring the integrity and safety of your projects. Whether you’re building a bookshelf or overhauling an engine, using the correct fasteners is paramount. By taking the time to learn the key distinctions, you'll save yourself time, money, and potential headaches down the road. So next time you're facing a bin of bolts, remember this guide, and choose wisely. Your projects (and your sanity) will thank you.

Black clover animes grand finale exploring the manga chapter conclusion

Unlocking automotive potential fuel efficiency secrets

Unlocking the power of pin connectors in wiring harnesses